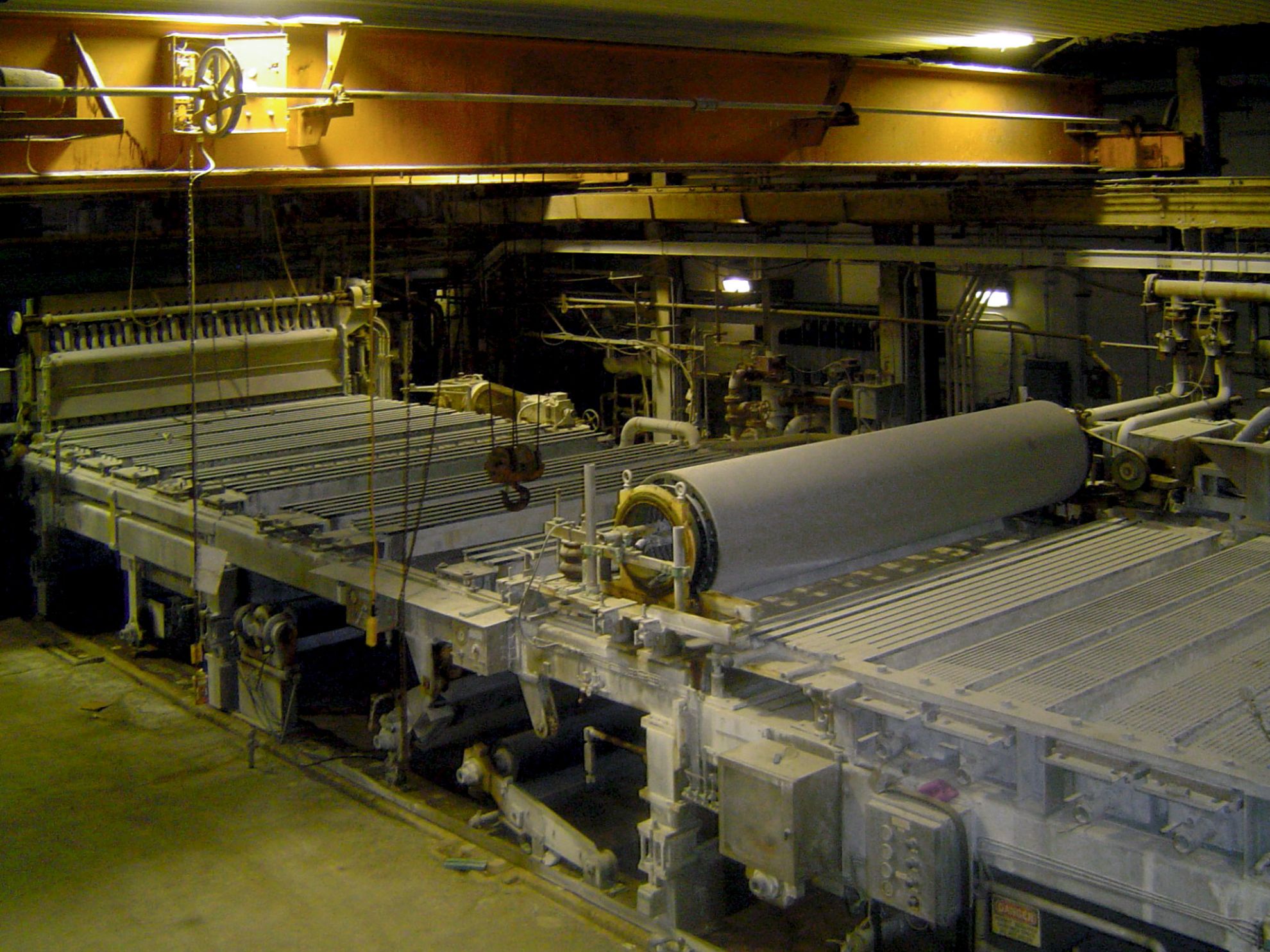

Paper Mill Equipment

Select Subcategory

Used Paper Mill Equipment for Sale. Including Pulp Mill, Power Plant, Steam Plant and other Surplus Papermaking Machinery .

Nash CL-402 Test: 93E8818 Inlet: 3" Outlet: 2.5" Center to Center Inlet and

126273

Nash CL-402 Test: 93E8818 Inlet: 3" Outlet: 2.5" Center to Center Inlet and Outlet: 18"Vacuum Pump

Nash CL3003 Test #: 9720126 Rpm: 500 C.i. Vacuum Pump

126275

Nash CL3003 Test #: 9720126 Rpm: 500 C.i. Vacuum Pump

Nash CL 6002G S/S 316 Clading: Body Cones Heads Shaft Diameter: 2.875" Posi

126276

Nash CL 6002G S/S 316 Clading: Body Cones Heads Shaft Diameter: 2.875" Position 4 Test #: Mc 01672 Ratio: 3.6 / 1 Drive Gear: 36 Teeth Driven Gear: 132 Teeth Vacuum Pump

Nash CL 6002G Test #: 69c-0105 Ratio: 3.6 / 1 Drive Gear: 36 Teeth Driven G

126277

Nash CL 6002G Test #: 69c-0105 Ratio: 3.6 / 1 Drive Gear: 36 Teeth Driven Gear: 132 TeethVacuum Pump

Nash Model CL 9002 Vacuum Pump. Manufactured In 2006.

123871

Nash Model CL 9002 Vacuum Pump. Manufactured In 2006.

Nash Model CL 9002G Vacuum Pump. Position 1. Manufactured In 2000. Test# 00

123872

Nash Model CL 9002G Vacuum Pump. Position 1. Manufactured In 2000. Test# 00M45122.

Nash Model 2BE3 72 Vacuum Pump Endshield head; Iron; Unused Storeroom Spare

126739

Nash Model 2BE3 72 Vacuum Pump Endshield head; Iron; Unused Storeroom Spare

Somarakis Vacuum Pump Model No. 6000 CFM; POS. 1; CL 6002 Equivalent; 10Õ t

126740

Somarakis Vacuum Pump Model No. 6000 CFM; POS. 1; CL 6002 Equivalent; 10Õ to 20" Mercury; Directly Interchangable w/ A Nash CL 6002 Series;

Nash SC3/7 Vacuum Pump; 1170 RPM; Iron NashSC3/7 99D0226

126743

Nash SC3/7 Vacuum Pump; 1170 RPM; Iron NashSC3/7 99D0226

Nash Vacuum Pumps CL 702 Vacuum Pump; Iron Casting

126744

Nash Vacuum Pumps CL 702 Vacuum Pump; Iron Casting

Goulds Model No. 3410 Split Case Pump 12x14x15; CF8M Stainless Steel Casin

126710

Goulds Model No. 3410 Split Case Pump 12x14x15; CF8M Stainless Steel Casing; 7-Vane Singe Straight Stainless Steel Impeller; 13.75" Impeller Diameter

Manchester Suction Couch Roll 142" Bearing Centers 125" Face 118.5" Drilled

126723

Manchester Suction Couch Roll 142" Bearing Centers 125" Face 118.5" Drilled Face 1/2" Hole Diameter 1" Roll Cover Thickness 25.31" Roll Diameter Bronze Cover

Beloit Suction Couch Roll 188" Drilled Face 201.5" Overall Face 230" Bearin

126733

Beloit Suction Couch Roll 188" Drilled Face 201.5" Overall Face 230" Bearing Centers 38" Diameter 5/8" Hole Diameter 7/8" Shell Thickness Rubber Cover Spare Rebuilt By Hamilton Machine Year 2010 Rebuilt So5355

111” drill face x 24” diameter Manchester suction press roll bronze shell 1

124200

111” drill face x 24” diameter Manchester suction press roll bronze shell 118” overall face 133.5” bearing centers. Suction box has 4” opening includes doctor and creeping assemblies.

Escher Wyss Suction Drum Roll; 137" Face; 128" Drilled Face; 36" Diameter B

126724

Escher Wyss Suction Drum Roll; 137" Face; 128" Drilled Face; 36" Diameter Bronze Cover

120” (3048mm) Face Width 2 or 4 Roll Kusters Calender 2 by 2 Tandem Compact

126805

120” (3048mm) Face Width 2 or 4 Roll Kusters Calender 2 by 2 Tandem Compact Soft Nip Calender by Hunt & Moscrop. Maximum Nip Pressure 1000 PLI; Swimming Roll Cover Hardness 91-92 Shore 'D'; Operating Speed Balanced for 280-800 Ft/Min. (85-243 M/Min.). Drive Roll Surface Hardness 540 D.P.N Drive Roll Surface Temperature 250 F Degrees Swimming With Hydrualic Drive Control Panel And Spare Rolls Mfg: Kusters.

244” Voith Janus 8-roll On-machine Calender. This Hot Soft Nip calender is

126031

244” Voith Janus 8-roll On-machine Calender. This Hot Soft Nip calender is balanced for a maximum speed of 4000 FPM. It Operated at 3000 FPM producing high gloss grade papers in line with a paper machine. The multiroll calender is the latest technology new in the early 2000’s. It includes the hot oil system and any available spare parts as well as drive components. The Voith Janus calender offers the option to produce standard newsprint in addition to SC grades in either the very top or very bottom calender nip. In the case of wood-free coated papers for example the Janus calender enables 50 plus to high-gloss grades. In the case of uncoated papers newsprint or improved newsprint can be produced in addition to SC qualities (SC-A SC-B). Available immediately.

292” Length 42”/60” Diameter Farrel Corporation Heavy Duty 2 wheel Roll Gri

124023

292” Length 42”/60” Diameter Farrel Corporation Heavy Duty 2 wheel Roll Grinder with floating heads. Capacity: Max. Roll Dia. on center with full size wheel- 42”; Max. Roll Dia. above centerline- 60”; Min. Roll Dia. ground on centerline- 7”; Max. Roll Face ground- 292”; Max. Carriage traverse- 320” plus; Max. Crown/Concavity of roll - .400”; Grinder Bed: Material – High grade Meehanite Iron; Ways – inverted “V” type cast separately from bed close grained alloy construction; Anchoring – 4 rows of special leveling screws spaced on 4’ centers and an equal number of hold down bolts; Headstock: Material – High grade Meehanite Iron; Work speeds rpm programmable - 4 – 24rpm; Work Motor D.C. - 20 hp 400/1600 RPM; D.C. Drive new 2010 – ABB; Wheel heads: Grinding Wheel Dia. std. - 20”; Grinding Wheel Face std. - 3”; Spindle speed range - 700 – 1750 rpm;Grinding wheel motors D.C. - 15 hp; D.C. Drives - Harland Simon/ABB (new); Infeed Assemblies: Rough wheel infeed hand wheels for manual feeding on each wheel head.; Carriage: Material – High grade Meehanite Iron; Carriage Speed programmable - 2 - 60 ipm; Carriage Motor - 5 hp D.C.; D.C. Drive - Harland Simon / Electroflyte; Traverse screw diameter - 4 5/8”; Carriage Ways center-to-center - 72”; Over all width of each way - 8 ½”; Over all length of carriage - 98 ½”; Swing rest design on carriage to support adjustable pivot supports and wheel assemblies; Directional reverse of carriage travel with use of reversing and safety over travel limit switches; Dimensions: Approximate size of inertia block required - 45’ x 9’6” x 4’; Approximate weight of machine - 140000 lbs. Includes: Tooling and Roll Stands; Crowning Devices for Manual Crown Control; Engineering Files and Operating Manuals on Roll Grinder; One rebuilt electrical system containing all DC Drives Motors Magnetic Starters Relays Fuses more.; One New Operator station containing all operator controls; controls include on/off switches and speed control for grinding wheels forward/reverse e-stop and speed control for carriage. On/off and speed control for roll drive included on control panel. Machine can be seen under power mechanically and electrically turned over.